AI based Quality ControlAdvanced Observability

AI based Quality Monitoring

For the Aquaculture Industry

Why we exist?

In today's seafood industry, quality control can be slow and subjective, leading to potential defects in shrimp products going unnoticed. Manual inspections are time-consuming, compromising quality and causing two critical issues:

- Increased FDA Shrimp Import Refusal: Meticulous FDA standards demand heightened scrutiny. We aim to exceed regulatory benchmarks, ensuring smoother imports.

- Unscalable Manual QC in Shrimp Factories: Manual processes hinder scalability. Our mission is to introduce innovative technologies for efficient and precise quality control.

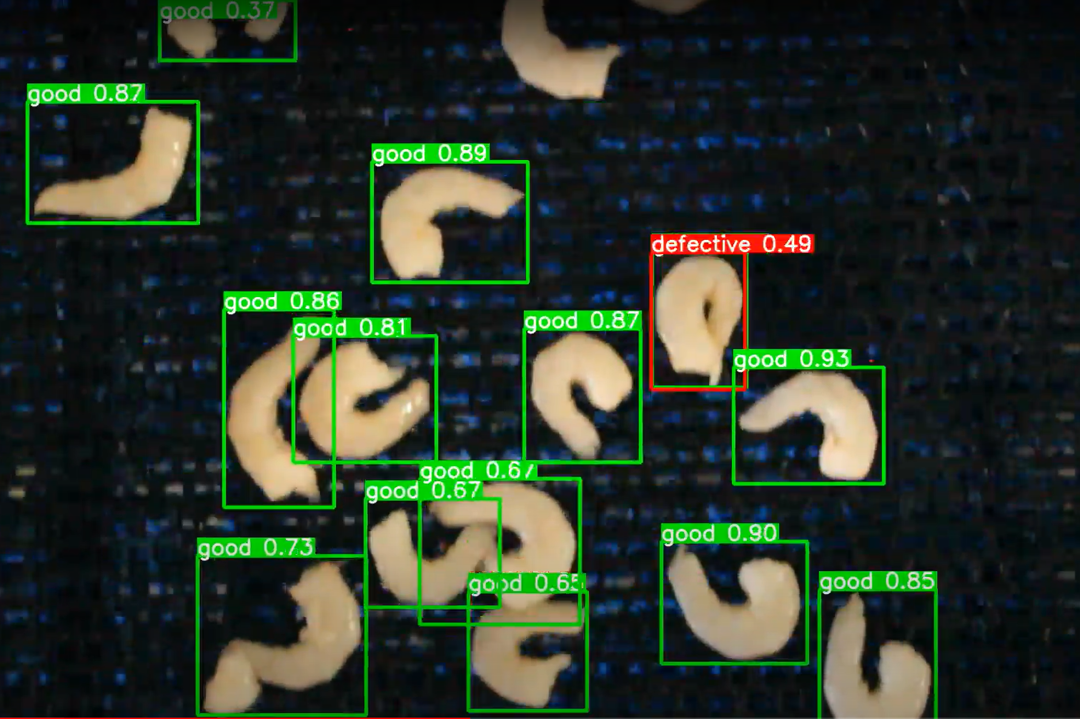

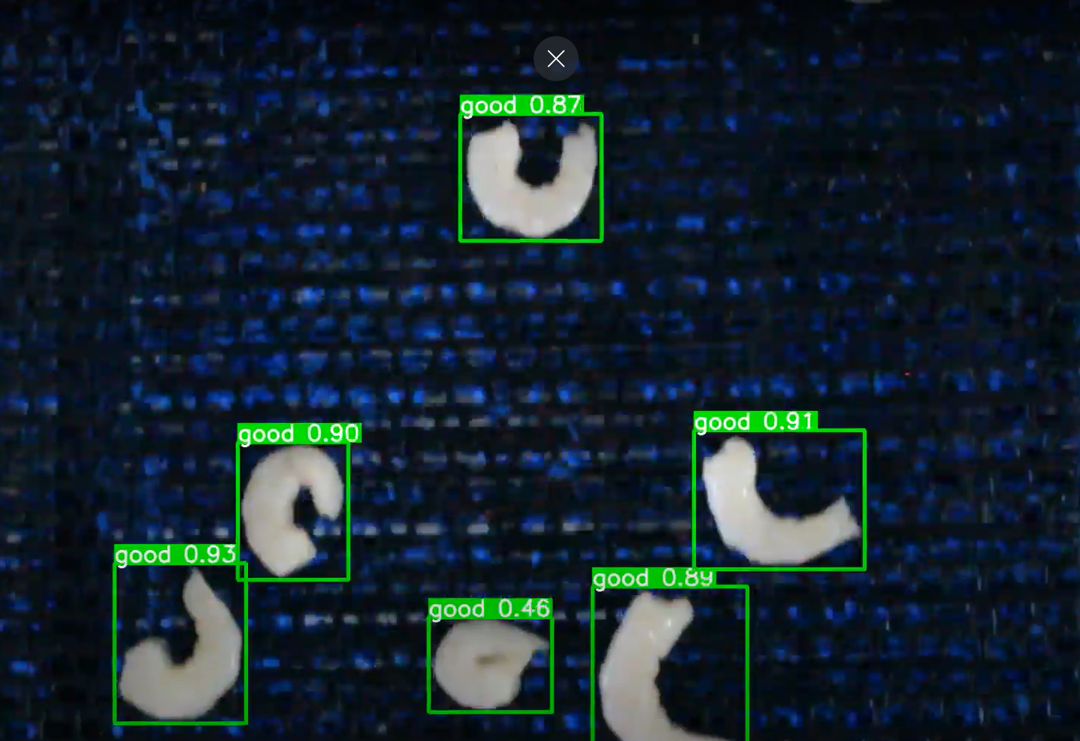

Our AI ensures top-notch shrimp quality

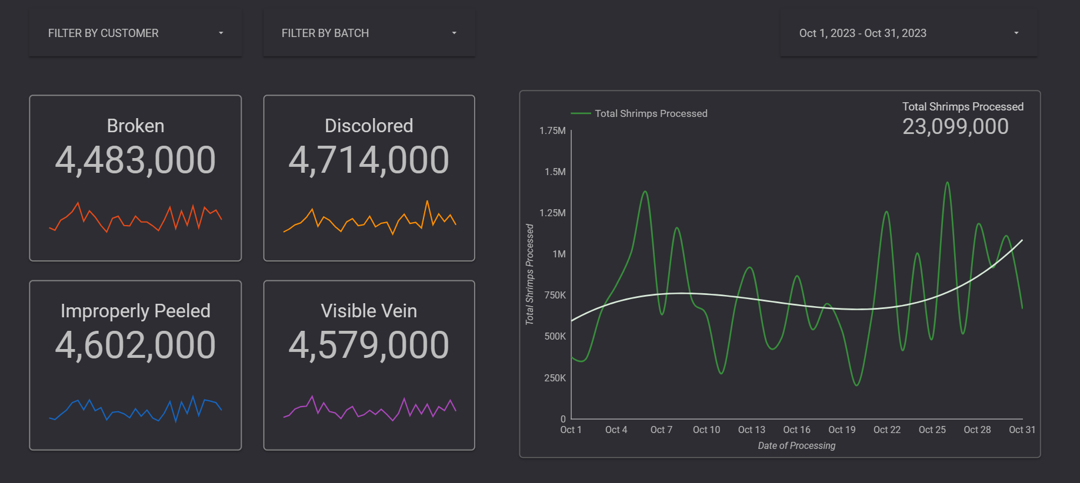

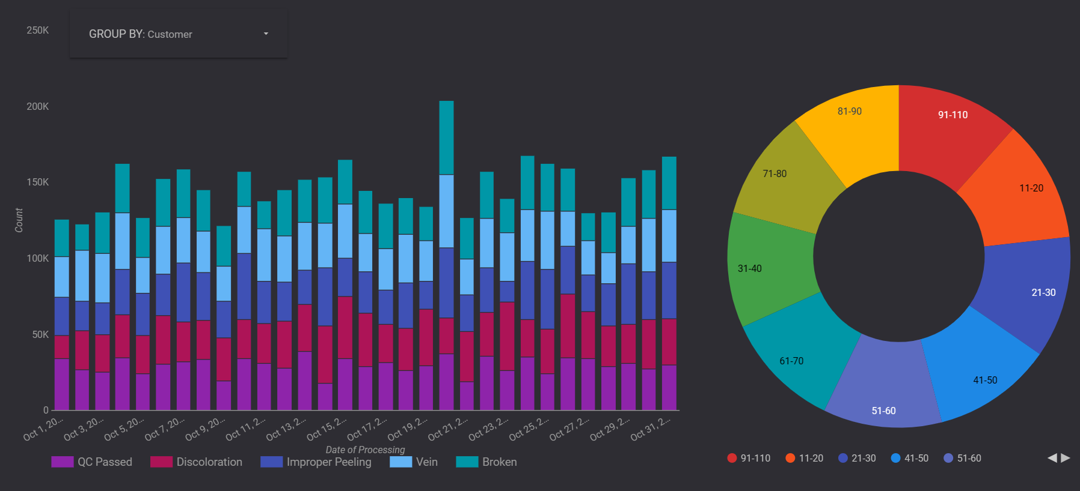

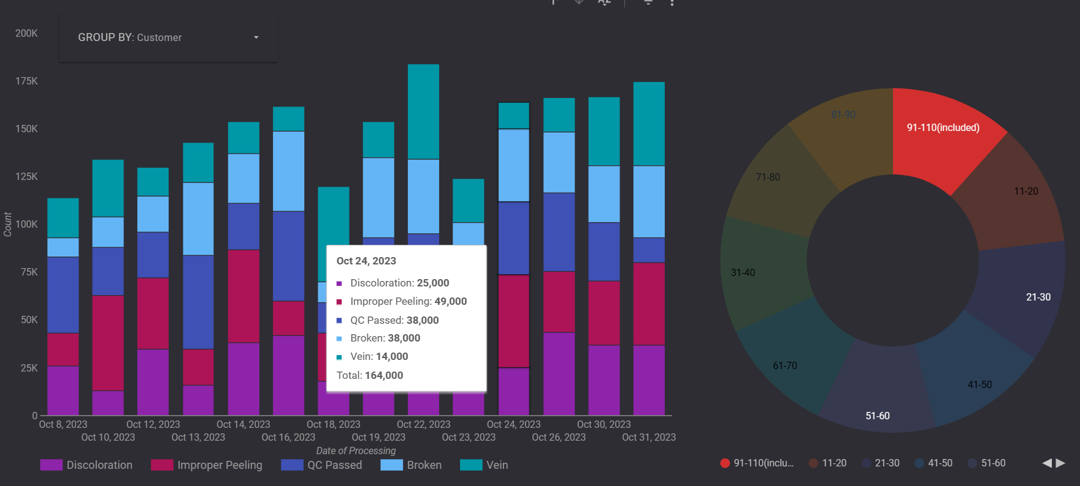

Rich yet Intuitive Observability Dashboard

FAQs

Still scrolling?

Don't suffer from rejections due to improper QC

777 Royal St George Dr,

Naperville, IL 60563

+1 (872)-221-7181

777 Royal St George Dr,

Naperville, IL 60563

+1 (872)-221-7181